Researchers from across Canada are now making use of the emerging neutron beam user program at the McMaster Nuclear Reactor to train students and acquire new knowledge about materials.

Source: Canadian Institute for Neutron Scattering (CINS)

Contact: webmaster@cins.ca

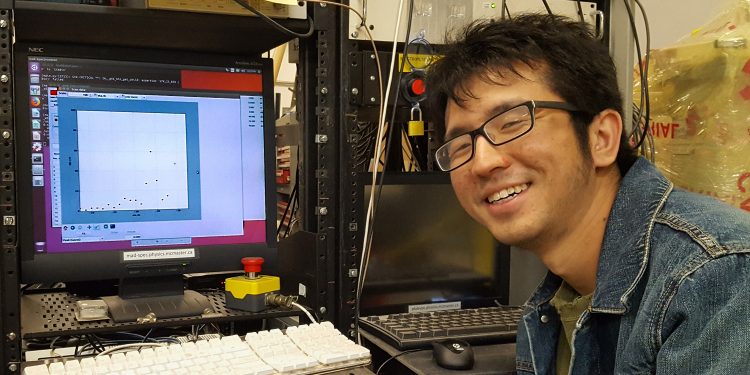

Image: Bo Yuan, a PhD student from the Physics Department at the University of Toronto, collects neutron diffraction data on the MAD beamline at the McMaster Nuclear Reactor. (Credit: Pat Clancy/McMaster)

Canadian researchers use neutron beams to make discoveries that have wide-ranging impacts in sectors such as energy, manufacturing, and even health. Neutron beams are versatile and irreplaceable tools for understanding the properties of materials, providing knowledge that often can’t be obtained any other way. And since materials make up everything around us, obtaining a better understanding of how materials work is often essential for technological advances.

The McMaster Nuclear Reactor building on the main campus of McMaster University in Hamilton, Ontario, Canada. (image: McMaster)

Following the March 2018 closure of Canada’s most powerful neutron source, the NRU reactor in Chalk River, the research community has been interested in fully leveraging the potential of the McMaster Nuclear Reactor (MNR) in Hamilton, Ontario (the community’s vision for this future is expressed through the Canadian Neutron Initiative).

“We now have the only neutron beamline in Canada that appeals broadly to the materials research community,” says Pat Clancy, the first scientist dedicated to operating the neutron beam lab at McMaster. “McMaster is also building a second, more powerful beamline that will be completed in 2019. Both facilities are meant to be national resources for research and education.”

In 2017, McMaster upgraded its existing beamline, known as the McMaster Alignment Diffractometer (MAD), and began providing support for users. These efforts have paid off with a large increase in MAD’s usage. So far in 2018, MAD has supported 13 experiments conducted by 17 users from 5 institutions outside McMaster: the University of Toronto, the University of Winnipeg, the University of Manitoba, l’Université de Montréal, and one private sector firm.

Professor Young‑June Kim of the University of Toronto and his graduate student Bo Yuan are among these users. Kim’s research aims to explore materials that can only be understood using quantum physics. One class of these materials is called ‘topological quantum materials.’ (Read our previous article about topological materials). Neutrons are a uniquely powerful tool for observing the magnetism of such materials.

“To study topological quantum materials with neutrons, we often need to produce them in a single-crystal form, and then there are preparatory steps, including evaluating the crystal’s quality and aligning the crystal, before full observations,” says Kim.

The McMaster Alignment Diffractometer (MAD) is located on beam port 6, outside the biological shielding around the reactor core. (Image: Pat Clancy/McMaster)

Kim and Yuan used MAD for two experiments. The first one evaluated the quality of various samples of cobalt titanium oxide crystals. The data from MAD enabled the researchers to identify the number, size, and orientation of the crystal grains in the samples—information that was essential for explaining data the team collected from the samples using the leading neutron beamline for quantum materials at Oak Ridge National Laboratory (ORNL) in Tennessee.

The second experiment Kim’s team conducted at MAD enabled the researchers to align samples of copper boron oxide according to the orientations of their crystal grains prior to a full-scale neutron beam experiment at the NIST Center for Neutron Research in Maryland.

Without access to MAD beforehand, we couldn’t have done the experiment at all within our allotted beam time.

“Although crystal alignments are sometimes routine preparations, our crystals in this case had very complicated crystal structures and were difficult to align,” explains Kim. “We got excellent data from our beam time at NIST, but without access to MAD beforehand, we couldn’t have done the experiment at all within our allotted beam time.”

Kim is among many researchers who face increasing competition for neutron beam time, especially now that Canada’s primary source is closed. In fact, the demand for beam time is two or three times greater than the supply at leading international neutron facilities like ORNL and NIST. Therefore, it’s important for Canadian researchers like Kim to make the most effective use of whatever beam time they can get—which increasingly involves visiting MAD to complete preparatory steps, and to give students hands-on experience, in advance of conducting larger experiments abroad.

Hands-on experience at MAD gives Canadian students a competitive edge by preparing them to perform experiments more effectively at world-leading neutron and x‑ray sources. Such research also imparts students with invaluable analytical skills that will serve them well in their future science and technology pursuits, including careers outside academic research.

What we’ve done with MAD so far is just the beginning.

Additionally, the McMaster beamline is allowing future nuclear engineers to gain firsthand insights into the principles of designing shielding for power reactors and other sources of radiation. For example, students in one undergraduate course in nuclear engineering use MAD for a demonstration experiment to determine how effectively various materials absorb neutrons produced in a reactor (as compared to how they absorb other forms of radiation).

“What we’ve done with MAD so far is just the beginning,” says Clancy. “We are developing more demonstration experiments for use in undergraduate and graduate classes that could be parts of other programs at McMaster or even other universities.”

The McMaster Nuclear Reactor’s capacity to increase the number and kind of experiments it supports is a cause for excitement in the research community. For instance, the new beamline that McMaster is building will have experimental capabilities for examining soft and biological materials, as well as for conducting engineering research into metallurgical processes. These new capabilities are very much in demand by Canadian industries and universities—but until now, researchers have had to go outside of Canada to access such capacity.

“There is a community of Canadian materials researchers that is looking for the McMaster Nuclear Reactor to expand further to fill some of the gap left by the loss of the NRU reactor,” explains Clancy. “MNR still has a lot of untapped potential for neutron beams, but significant investment is needed to make full use of it. We’re working with the research community and funding agencies to explore the possibilities.”

McMaster’s efforts toward this future are coordinated with the research community under the Canadian Neutron Initiative. The Canadian Neutron Initiative seeks to establish a new framework that will ensure Canadians can access neutron beams for world-class research and innovation in materials as well as training students for highly-skilled careers. Such access would be based on partnerships with leading neutron-beam facilities abroad as well as fully exploiting domestic, university-based capabilities, including the McMaster Nuclear Reactor.