Researchers from Western University accessed the CNBC to generate knowledge for safe storage of nuclear waste.

Source: Canadian Neutron Beam Centre (CNBC)

Contact: cnbc@cnl.ca

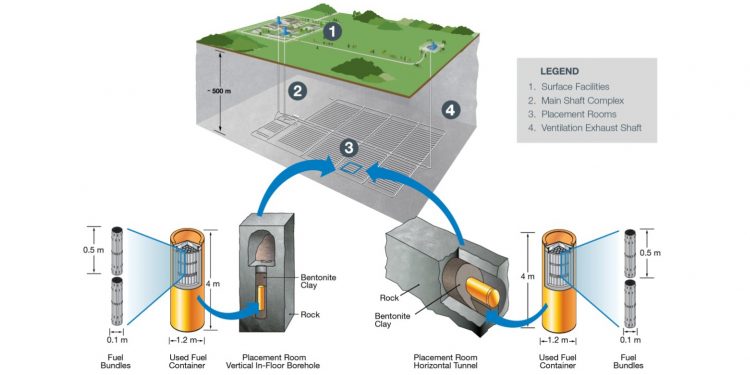

Image: Deep Geological Repository (NWMO)

Demonstrating safe, long-term means of storing used nuclear fuel will increase assurance of nuclear safety and security. Understanding and avoiding cracking in the pressure tubes in the core of a nuclear reactor is important to their economic, safe and reliable operation. What both of these areas have in common is the need to study how metals degrade, and specifically, the role of thin films of material that grow on metals.

A green protective layer naturally colours the copper roofs of the Confederation Building and protects the copper beneath it. Image: Public Works and Government Services Canada.

The exceedingly thin films on many metal surfaces have allowed us to construct a metal-dependent society, comprising items ranging from automobiles to buildings to biomedical implants and beyond. One beautiful and familiar example of such a protective layer can be seen in the green patina that colours the copper roofs of the Parliament of Canada buildings.

Without the protective layer, all of our structural metals would be unstable when directly exposed to air or water. Protective oxide films only nanometers thick often form spontaneously on the surface of a metal, providing a barrier between the metal and its environment and slowing or stopping degradation processes such as corrosion.

Because of the importance of thin oxide films to the performance and longevity of metallic structures, Dr. Jamie Noël from Western University has been collaborating with Dr. Zin Tun from the CNBC to develop and use combined electrochemical and neutron reflectometry techniques to help determine fine details of the nature of oxide layers on metals. Neutron reflectometry allows one to determine the structure and composition of surface layers on a subnanometre scale, by measuring how well neutrons reflect from a material’s surface, which acts like a mirror. The union of electrochemistry with neutron reflectometry allows measurements to be made of materials and interfacial properties that are unobtainable by any other means, while they are functioning and exposed to the environment in which they would normally reside.

Successful experiments in used nuclear fuel storage and in reactor pressure tube cracking are just a few examples of the research for which Dr. Noël has accessed the CNBC since its neutron reflectometer was commissioned in 2007. He has studied oxide film growth on titanium alloys to help understand their corrosion resistance, which is critical for their possible use to fabricate containers for permanent safe disposal of spent nuclear fuel. He has also probed the conditions under which hydrogen atoms can penetrate the oxide film on zirconium alloys, information that is vital to understanding and avoiding hydrogen-induced cracking in the pressure tubes in the core of a nuclear reactor.