The super-ambitious ‘Internet of Things’ would allow smart devices everywhere to gather, share, and respond to data—and one Simon Fraser University chemist is making breakthroughs in understanding the materials that have just the right electro-mechanical properties to turn that vision into a reality.

Source: Canadian Institute for Neutron Scattering (CINS)

Contact: webmaster@cins.ca

Image: The Internet of Things would enable efficiencies in every area of our society. (Shutterstock)

“Access to neutron beams has been essential to our discoveries,” says Ye.

Although piezoelectrics might not be on the tip of most people’s tongues, these materials are frequently at work behind the scenes in large and small ways. For instance, they’re critical to many medical diagnostic tools using ultrasound. They’re responsible for precisely controlling fuel injection in car engines, which helps to save fuel and reduce emissions. They’re integral to the remote sensors that cars use to alert drivers to such hazards as low tire pressure and objects in the vehicle’s path. They help to make smart phones ‘smart’ by backlighting phone screens, controlling the zoom feature on cameras, and filtering out noise during calls. They enable printers to put ink on the exact right spot on the page, and they deliver the precise amounts of materials needed in a 3D printer’s head. They’re used by companies like IBM to precisely control ‘printing’ of the 30 billion transistors in a computer processor’s chip. And that’s just the tip of the iceberg.

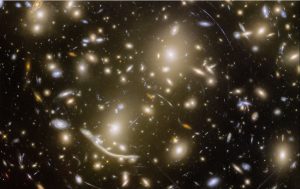

The Hubble Space Telescope uses the amazing electro-mechanical properties of piezoelectric materials to resolve images of galaxies that are billions of light-years away. (Image: Hubble)

In simple terms, piezoelectrics are materials that either generate electrical signals in response to an external force (i.e., sensing), or else generate a force by expanding or contracting in response to an electrical signal (i.e., actuating). Piezoelectrics’ actuating function is useful to engineers for many applications, such as developing control systems for positioning movable parts with nanometre precision. For example, piezoelectrics are used in the Hubble Space Telescope to allow scientists on the ground to control its mirrors with such incredible precision that it can resolve images of neighbouring galaxies that are billions of light-years away.

In fact, the United States Navy believes that improved piezoelectrics is a key to improving sonar technologies to better detect underwater threats and to avoid detection by opposing forces. That’s one reason why the U.S. government is sponsoring the work of Simon Fraser University’s Zuo-Guang Ye, one of the world’s leading experts on the inner workings of these materials.

However, if piezoelectrics could be made to be more sensitive, more powerful, and more compact, then their reach would extend well beyond space and military applications.

Professor Zuo-Guang Ye of Simon Fraser University.

For instance, Ye notes the potential benefits to healthcare, where “better piezoelectrics are needed for improving medical diagnostic and treatment technologies like ultrasound.” He also points to the enormous potential for piezoelectrics to improve laparoscopic surgeries (i.e., operations performed by inserting remotely operated cameras and tools into the patient through a small incision). These ‘minimally invasive’ surgeries, commonly used for procedures such as removing gall bladders and implanting cardiac stents, greatly improve patient recovery times—but there is still a lot of room for improvement. “Laparoscopic surgeries need better piezoelectric materials in order to deliver more power to tiny surgical devices inside the patient,” explains Ye. “More ultrasonic power could help break up large kidney stones, for example.”

In addition to enabling advances in healthcare, better piezoelectrics are also needed to help turn the conceptual ‘Internet of Things’ into a reality. This concept envisions billions of devices – home, business, civil, and even medical – all being wirelessly connected to each other through sensors, actuators, and transmitters that work in tandem to transmit the data needed to operate most effectively with minimal human intervention. Experts predict that the Internet of Things could change everyday life in countless ways, such as by making it possible to diagnose breast cancer with a breath sample or automatically adjusting traffic lights to most efficiently accommodate up-to-the-second traffic flows—and these are just two examples in a sea of millions of ideas.

Better piezoelectrics are also needed to help turn the conceptual ‘Internet of Things’ into a reality… Improved piezoelectrics could eliminate the need [for billions of] devices’ batteries.

Higher-performance piezoelectrics could help to shrink the size of the sensors, actuators, and transmitters used in these next-generation devices, and could also more precisely control the bandwidth used by each device—which is important, since the airwaves are already crowded. And since piezoelectric materials have a unique ability to generate electricity, improved piezoelectrics could also be used to harvest significant amounts of energy from the environment to power billions of these sensing and transmitting devices, thereby eliminating the need to continually replace the devices’ batteries.

A material’s atomic ‘phase’ explains much of its macroscopic behaviour. Salt has a cubic atomic phase, which explains why its crystals are sometimes cubic. (Image: Smithsonian Institute)

Today, the dominant piezoelectric material is a ceramic known simply as PZT due to its composition of lead zirconate (PbZrO3) and lead titanate (PbTiO3), which together form a type of alloy known as a ‘solid solution.’ And while the global PZT market is valued at over $12 billion per year, scientists still do not fully understand what it is, exactly, that gives PZT and other piezoelectrics their amazing ability to expand and contract so precisely—or, even more quizzically, what allows them to generate their own electricity. And until that mystery is solved, improvements to piezoelectrics will be stunted.

For the past 60 years, researchers have been using every scientific tool at their disposal to gain insights into how piezoelectric materials work, but with limited success. That’s because PZT is a complex combination of two opposite types of materials. In some ways it is like glass, in which the molecules are arranged randomly (a fact that makes glass behave like a very slow-moving liquid). In other ways, it’s like table salt—the opposite extreme, wherein the atoms are arranged in a single, regular cubic pattern. Indeed, PZT contains regions where the atoms or molecules are randomly arranged, like they are in glass, as well as regions that are arranged in a much more orderly fashion, like they are in salt.

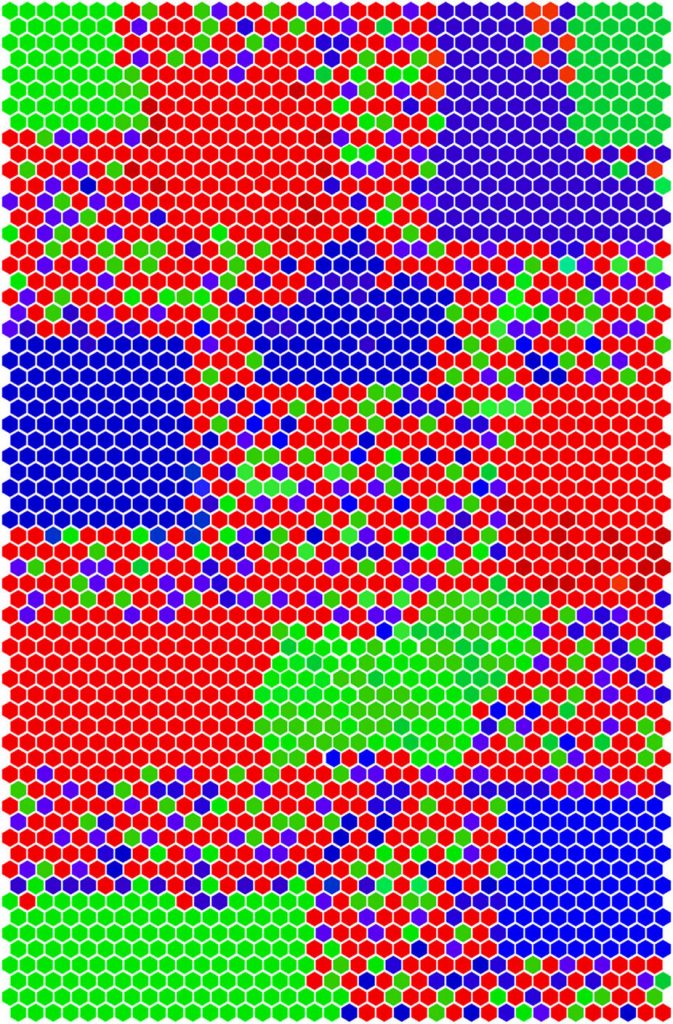

A simplified illustration of PZT’s complexity. Red, green, and blue dots represent distinct groups of similar atomic phases, with shades of each color representing variations within in the group. (image: doi:10.1038/ncomms6231)

To complicate matters further, even the more orderly regions of PZT can take on one of many ‘phases’ (i.e., atomic patterns). These phases may persist over an extremely short distance—e.g., across only a few molecules (about one nanometre)—which makes them even more challenging to observe. What’s more, these phases vary depending on the ratio of the PZT’s two constituent molecules, PbZrO3 and PbTiO3. And even the tiniest differences in some of the atoms’ positions with respect to the phase seem to lead to big differences in the PZT’s macroscopic behaviours, including its piezoelectric properties. To add to the complexity, the phases near the surface of the material can differ from the ones deeper inside.

This unusual composition has made it difficult for researchers to find the right tools to study PZT. Some tools are good for studying glass-like materials, while others, such as neutrons and x‑rays, are ideal for probing orderly materials. Neutrons and x‑rays can still be very effective in cases where the regular pattern is quite complicated, or where there are multiple phases, as is common in metallic alloys. Even so, the complexity of piezoelectric materials has meant that scientists still don’t have all the answers about what phases exist in PZT and other piezoelectric materials, or about the conditions under which these phases are present.

Illustration of the simplest phase (i.e., the prototypical crystal structure) of the lead zirconate (PbZrO3) or lead titanate (PbTiO3) that is found in many high-performance piezoelectric materials. The length of each edge is only about 0.4 nanometres long (image: Ye).

A major breakthrough in understanding the inner workings of these materials came when Ye’s research team successfully grew a series of high-quality single crystals of PZT, each with a different ratio of the two constituent molecules. These millimetre-sized crystals allowed Ye and his international collaborators to use neutron beams to obtain more precise data than was previously possible. They also used specialized neutron beam techniques to gain information about the various phases that persist over just a few nanometres of PZT. They accessed these specialized techniques at world-leading neutron beam facilities, such as the NIST Centre for Neutron Research in the U.S., the ISIS neutron beam facility in the U.K., and the Institut Laue-Langevin in France.

These specialized neutron beam techniques, combined with complementary experimental methods, led the researchers to several important discoveries. First, the early findings clearly observed one of PZT’s key phases, dubbed the ‘M phase’—a phase whose very existence was being questioned by some scientists at the time of the findings’ publication in 2010 (doi:10.1103/PhysRevB.81.172103).

Ye’s early findings solved a second mystery as well. Even those scientists who had previously accepted the existence of the M phase had been searching without success for a ‘missing boundary’—that is, the conditions under which the M phase was converted into a second phase, dubbed the ‘R phase.’ Ye’s findings cast doubt on whether that boundary was truly missing at all, because they showed that the M and R phases actually coexisted in many cases (doi:10.1103/PhysRevLett.105.207601).

They also found that the MA phase leads to stronger piezoelectric behaviour than the MB phase, and they were able to explain why this was the case.

In subsequent findings, Ye and his collaborators did find a missing boundary— but it wasn’t between the M and R phases at all. Rather, it was between two variations of the M phase, MA and MB. Furthermore, they showed that the occurrence of the two M phase types depended on the relative proportion of the two constituent molecules PbZrO3 and PbTiO3 in the material. Perhaps most exciting of all, they also found that the MA phase leads to stronger piezoelectric behaviour than the MB phase, and they were able to explain why this was the case. Notably, the team’s insights into the MA phase can be applied to a variety of other similar materials, which was why these findings warranted publication in one of the top multidisciplinary scientific journals, Nature Communications, in 2014 (doi:10.1038/ncomms6231).

With this improved understanding, Ye and his collaborators were then able to make another surprising observation, that not only sheds light on the mechanism behind the high piezoelectricity of PZT, but could also open up a whole new class of materials for use in spintronic technology, which could be the basis of more powerful computers and devices in the future.

With this improved understanding of the inner workings of PZT, Ye and his collaborators were then able to make another surprising observation about this material, published in Nature Communications in 2016 (doi:10.1038/ncomms12385). Using electron microscopy, they discovered that the electric polarization at the interface of domain walls can actually rotate—even though PZT belongs to the large class of materials where such polarization has always been observed as being fixed in place. This discovery not only sheds light on the mechanism behind the high piezoelectricity of PZT, but it could also open up a whole new class of materials for use in spintronic technology, which encodes information in the direction of an electron’s magnetic field—and which could be the basis of more powerful computers and devices in the future.

In addition to exploring PZT, Ye has made significant observations in two other highly complex and poorly understood piezoelectric materials, designated as PMN-xPT and PZN-xPT. These materials are the ones used in the Hubble Space Telescope because they have the greatest known piezoelectric effects (i.e., as much as three times that of PZT). Like PZT, they are both contain PbTiO3 and a lead-based oxide: Pb(Mg1/3Nb2/3)O3 or Pb(Zn1/3Nb2/3)O3, respectively. But unlike PZT, they belong to a category of piezoelectric materials known as ‘relaxors,’ in which the electric polarization is arranged randomly.

Enhanced understandings [such as Ye’s findings] are essential for scientists to further refine the sensing and actuating capabilities of piezoelectric materials, and to make more sensitive, more powerful, or more compact devices

Notably, relaxors have yet to be fully defined scientifically. Thus, “We needed to study them [PMN-xPT and PZN-xPT] in detail because there was no scientific consensus on the phases that exist in these materials, which was hampering our understanding of what causes their exceptional piezoelectric properties,” says Ye. “In parallel, questions about how relaxors work have persisted in the face of decades of research, partly because there exists no rigorous understanding of what causes the intricate ‘relaxor behaviour’.”

The discoveries made by Ye and his collaborators have been helping to resolve the scientific controversies about relaxors. For instance, bolstered by the success of their earlier neutron beam analyses of PZT, Ye’s team used neutron beams and other tools to conduct a systematic comparison between PZT and PMN-xPT. These two materials are believed to be identical in many respects, providing the ideal test case to isolate the factors that cause the latter material to be a relaxor and produce extremely high piezoelectric behaviour.

In findings published in the prestigious multidisciplinary journal Proceedings of the National Academy of Sciences in 2014 (doi:10.1073/pnas.1314780111), the researchers showed that the key difference between these two materials was the presence of ‘strong random electric fields’ in PMN-xPT, and that these fields multiplied the relaxor’s piezoelectric behaviour. The findings provided persuasive evidence that strong random electric fields should be considered fundamental to relaxor behaviour and, hence, used as a characteristic feature to define relaxors.

Twenty years of extensive study had failed to establish how these polar nanoregions were connected to piezoelectricity… Not only did the researchers show that these polar nanoregions in fact caused a majority of the material’s hitherto unknown piezoelectric behaviour, they also revealed the mechanism by which these tiny regions have such a large effect on the properties of the material as a whole

Building on this success, Ye and his collaborators then tackled another critical scientific gap. Twenty years earlier, scientists had discovered nanoscopic regions within PMN-xPT and PZN-xPT where the electric fields point in different directions than the fields in the bulk of the material, called “polar nanoregions.” Yet extensive study had failed to establish how these polar nanoregions were connected to piezoelectricity.

The researchers collected further experimental observations of these tiny regions using x-rays, and built computer simulations that used the phase data gathered from both the x‑ray and neutron beam experiments. The results were illuminating: not only did the researchers show that these polar nanoregions in fact caused a majority of the material’s hitherto unknown piezoelectric behaviour, they also revealed the mechanism by which these tiny regions have such a large effect on the properties of the material as a whole. These conclusions were published in Nature Communications in 2016 (doi:10.1038/ncomms13807).

“Access to neutron beams has been essential to our discoveries,” says Ye. “They are critical for detecting the nanometre-scale variations in the phases, and for observing the phases deep inside rather than just at the surface. We have showed that the precise identification of these phases is key to understanding piezoelectric behaviour.”

Such enhanced understanding is essential for scientists to further refine the sensing and actuating capabilities of piezoelectric materials, and to make more sensitive, more powerful, or more compact devices. Indeed, according to Ye, “This knowledge is needed to design higher-performing piezoelectrics that will impact healthcare, the Internet of Things, transportation, energy, and a host of everyday consumer products, even though you may not even realize they are there.”